Growth Takes Flexibility

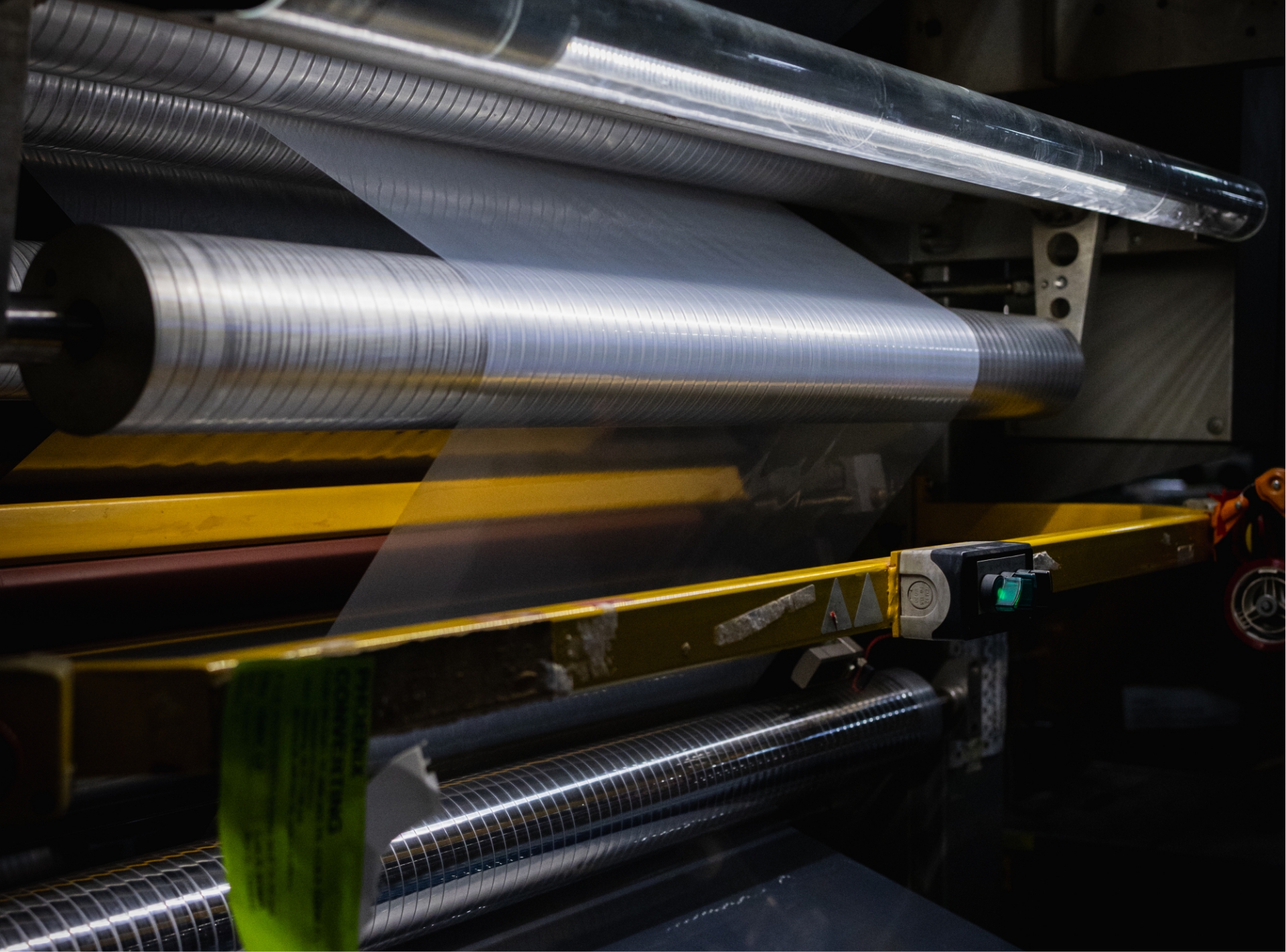

Flex Pack is a national producer of flexible packaging solutions that help growing brands care for people and planet alike.

Through our start-to-finish partnership, we can solve any packaging need.

We love helping our partners launch new brands.

Our capacity can help you expand your product lines.

We've got the flexibility to help you grow.

Our expertise can help you save time and money.

We can help you make an environmental difference.

We love helping our partners launch new brands.

Our capacity can help you expand your product lines.

We've got the flexibility to help you grow.

Our expertise can help you save time and money.

We can help you make an environmental difference.